EMU-Air and EMU-Liquid

- light construction for flexible use

- equipped for water / air cooling

- robust, flush fitting electric connections with a metal plug locking device

- quick heating time with optimum heating capacity

- quick cooling time due to integrated cooling channels

- optimum pressure and temperature distribution

An application film can be found here.

Pressure Bag

- robust rubber pressure bags with aramid reinforcement

- shape: rhombic 16° 42‘; 22°, rectangular 90°

- uniform pressure by the use of pressure bags

- either air pressure or a water/glycol mixture can be used as pressure medium

- when using air pressure the surface pressure is max. 70 N/cm² (100 psi)

- when using water/glycol mixture the surface pressure is max. 140 N/cm² (200 psi)

Various systems are available for pressure build-up:

EMU-Air with control box

- surface pressure up to max. 70 N/cm² (100 psi)

- with safety valve and pressure gauge

EMU-Liquid with pressure water pumps

- pressure medium: water/glycol mixture

- pressure range: 70 – 140 N/cm² (100–200 psi)

- with safety valve and pressure gauge

- also suitable for draining pressure bags

- 400 V, 50 Hz *

Portable type

- capacity: approx. 9 liter/min

- weight: approx. 25 kg

- complete with tubular frame

- additional tank (30 or 50 liter) required

- capacity: approx. 15 liter/min

- weight: approx. 54 kg

- complete with protection frame

- additional tank (from 50 liter) required

- compatible with SPLICE WATCH

Mobile type

- capacity: approx. 15 liter/min

- weight empty : approx. 100 kg

- tank volume: 100 liter

- complete with chassis on solid tires

- additional 100 liter tank available (mobile without pump)

- compatible with SPLICE WATCH

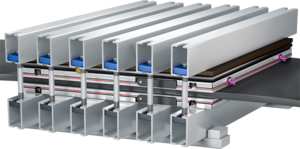

Heating plates

- flexible heating plates and pressure bag system adapt to the conveyor belt's surface during splicing

- particularly easy to transport due to the low weight of the single parts and the small dimensions

- uniform distribution of pressure due to WAGENER surface pressure system

- flexible heating plates in sandwich construction

- shape: rhombic 16° 42‘; 22°, rectangular 90°

- low individual weight of heating plates

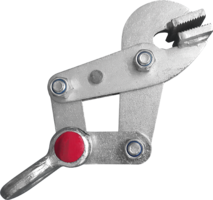

Cross Beams for pressure bag system

- light cross beams made of high-strength aluminium alloy

- maximum tensile and bending strength with minimum weight

- designed to be robust and to take up little space

- high safety standards due to insertion of the tensioning bolts with safety pins in the cross beam profile

- spacing rails for correct and secure assembly of the cross beams are included with the press

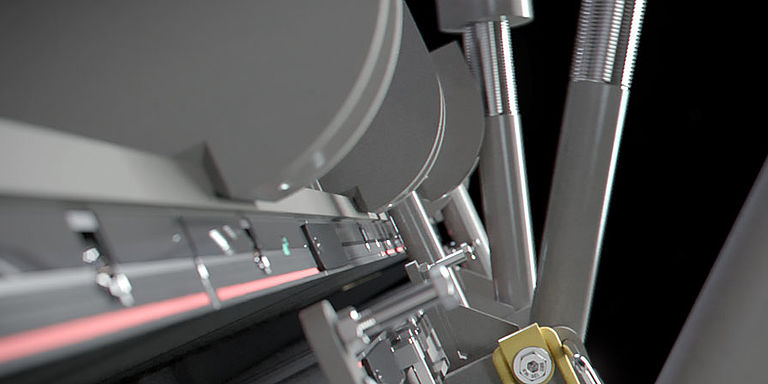

Vulcanizing Press Type EMU DUO

Features

- one vulcanizing press for two applications

- rectangular splices

- rhombic / bias splices

- well-known technology combined with highest safety

- flexible heating plates in sandwich construction, consisting of cooling profile, silicone heating element and insulating plate

- electronic control box

- light cross beams made of high-strength aluminium alloy

- surface hydraulic via pressure bag with aramid reinforcement

Control box with electronic temperature control system

- electric connection as per CEE standards

- exact temperature reading in each heating plate via thermo sensor PT 100

- electronic controller with digital display of setpoint and actual temperatures

- quick and simple programming of the electronic temperature control

- in case of electronic control failure, manual operation is possible

- the controller tolerance is only about 1% of the set value

- timer

- differential monitoring of the individual heating circuits

- optional: AC power outlet 230 V at 400 V, 50 Hz, 3 Phase+N+PE

| Control box | Input | Output |

|---|---|---|

| 2-plug | 400 V, 32 A | 2 x 16 A |

| 4-plug | 400 V, 63 A | 4 x 16 A |

| 2-plug | 400 V, 63 A | 2 x 32 A |

Any questions? Please contact us here.

* Other voltages on request