Vulcanizing Presses HYDRAULIC

- high level of safety by inserting traction bolts into the cross beam profile

- conventional, robust heating plates combined with hydraulic pressure systems allow splicing even on partially worn belts

- heating plate with air or water cooling

- exact temperature regulation via an electronic control box

- easier and faster pressure buildup by using a piston hand pump or motor pump unit

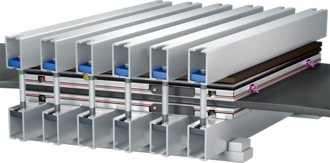

Heating plates

- heating plates of frame-type construction, made of a highquality corrosion-resistant aluminium alloy

- shape: rhombic 16° 42’; 22°, rectangular 90°

- optionally available with air and/or water cooling

- robust, flush fitting electrical connections guarantee safe operation

- optimum pressure and temperature distribution

- minimum temperature tolerance over the entire heating plate

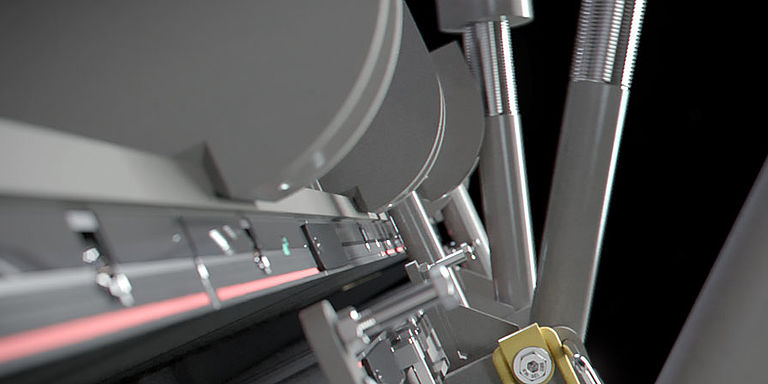

Cross beams with hydraulic pressure system

- special profiles made of high-alloy aluminum

- maximum tensile and bending strength with minimum weight

- built-in protection against hose breakage, the cross beam pressure being maintained in the event of a hose breakage or a sudden pressure drop

- compact high-pressure hydraulic light metal cylinders for uniform surface pressure

- high quality thermal insulation made of u-shaped fibre glassreinforced polyester in the top cross beam

- the surface area of the lower cross beam is covered with a wear-resistant insulating material

Pumps

- reciprocating piston hand pump or motor-driven pump

- distributor

- high-pressure hoses

- hydraulic oil

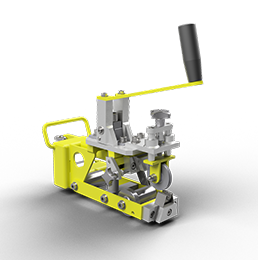

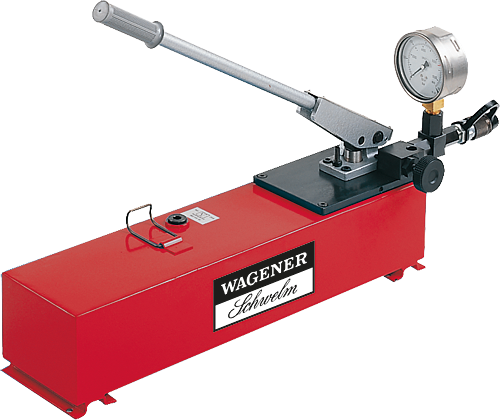

Reciprocation piston hand pump

- pressure limited to 450 bar

- oil filling 8 liter (usable oil volume = 6,8 liter)

- automatic switchover from low-pressure operation to high-pressure

- pressure gauge for pressure control

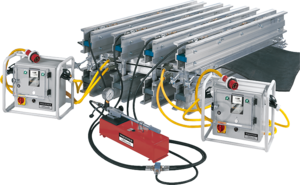

Motor-driven pump unit

- pressure limited to 450 bar

- supplied complete with tubular protective frame, pressure hose coupling and valves

- 400 V, 50 Hz *

- capacity 1,1 kW

- filling volume hydraulic oil: 17 liter or 35 liter

Hose distributor

- matches the number of cross beams

Control box with electronic temperature control system

- electrical connection as per CEE standards

- exact temperature reading in each heating plate via thermo sensor PT 100

- electronic controller with digital display of setpoint and actual temperatures

- quick and simple programming of the electronic temperature control

- in case of electronic controll failure, manual operation is possible as well

- the controller tolerance is only about 1% of the value set

- timer

- differential monitoring of the individual heating circuits

- optional: three-phase current- or single-phase power outlet at 400 Volt

| Control box | Input | Output |

|---|---|---|

| 2-plug | 400 V, 32 A | 2 x 16 A |

| 4-plug | 400 V, 63 A | 4 x 16 A |

| 2-plug | 400 V, 63 A | 2 x 32 A |

Any questions? Please contact us here.

* Other voltages on request