Vulcanizing presses

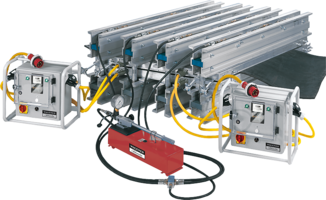

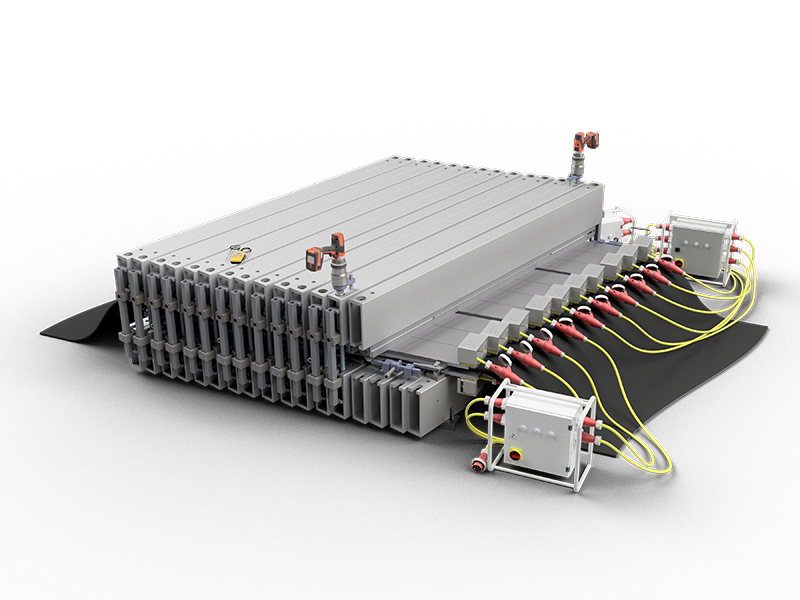

KLIV® - Module

- available press sizes for conveyor belt widths from 400 – 1400 mm

- compact press modules with integrated pressure and heating/cooling elements

- the maximum weight of the heaviest component is approx. 75 kg

- the ideal equipment for the vulcanizing of small and medium belt widths up to 1400 mm

- simple and efficient

- fully automatic ceramic heating system

- Hydro-mechanical system for uniform pressure

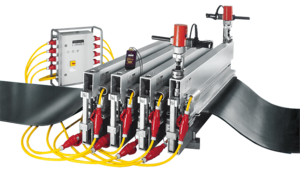

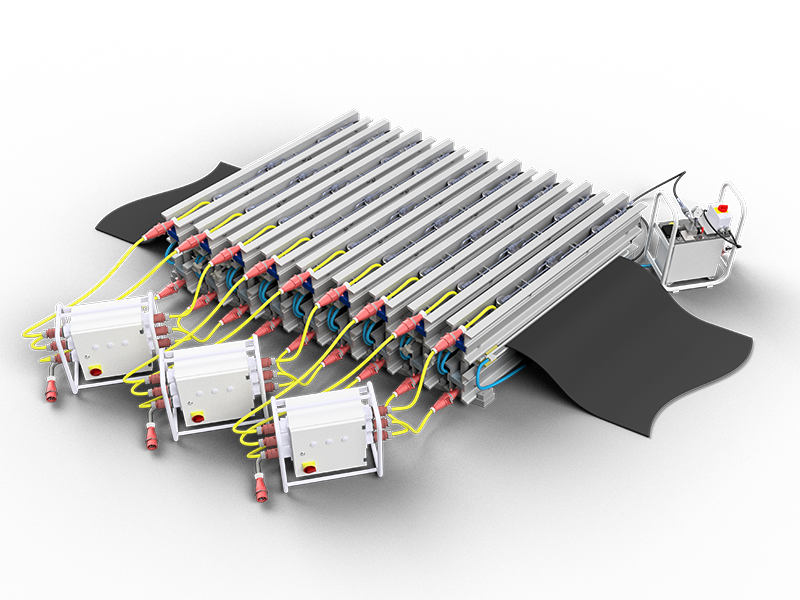

KLIV® - Combi

- available press sizes for all conveyor belt widths, particularly wider than 1400 mm

- pressure traverses, heating/cooling elements and pressure elements of this system are designed as individual units

- all press components are easy to handle even in cases of belt widths up to 3200 mm

- any combination with regards to length and width of the vulcanizing area is feasible

- the optimum unit construction system

- fully automatic ceramic heating system

- Hydro-mechanical system for uniform pressure

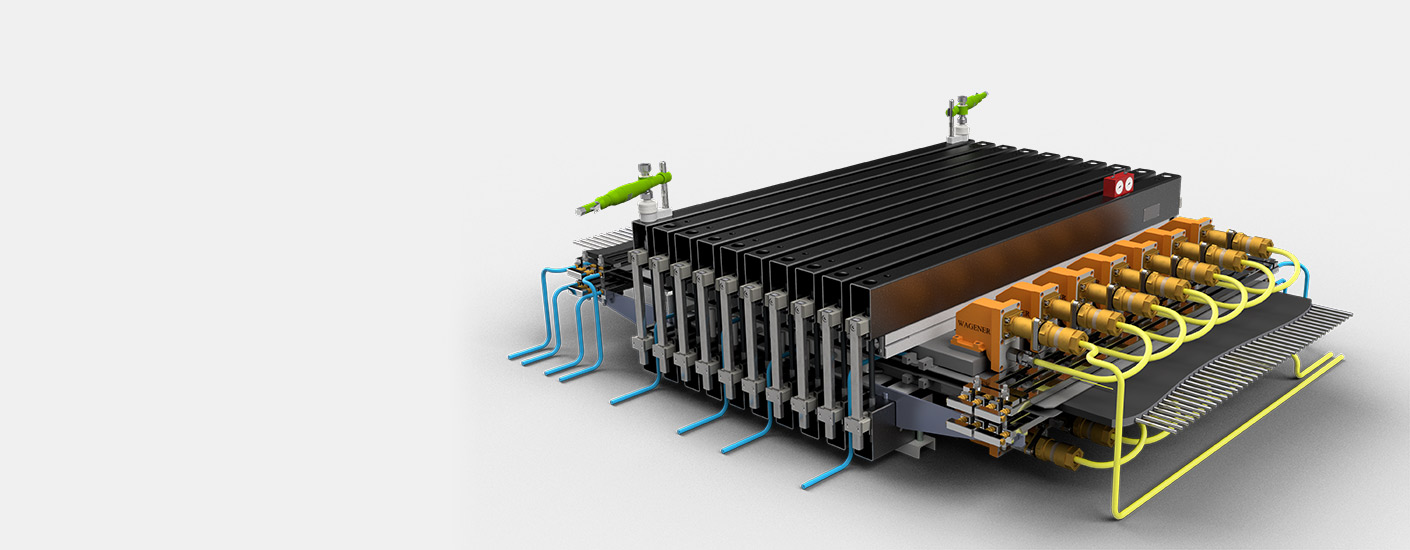

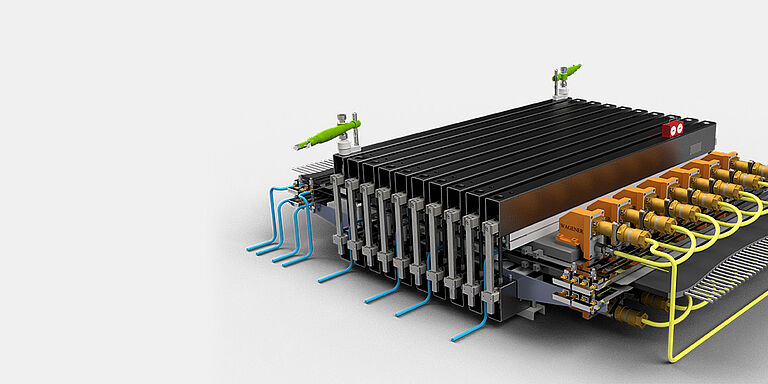

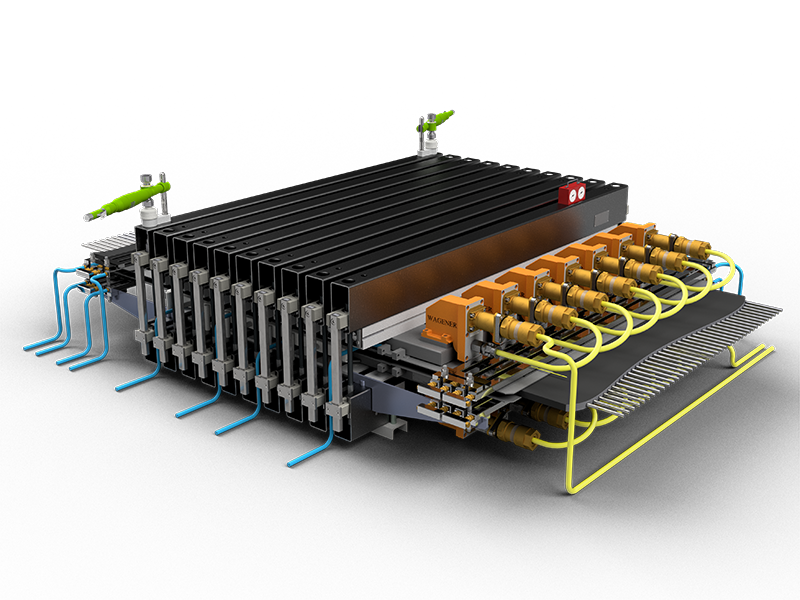

KLIV® - Cycon-Module

- KLIV - heating elements with cooling channels

- distributor boxes for connecting the heating elements to the mains supply

- pressing sheets for a uniform distribution of temperature and pressure

- hydraulic traverse beams for pressure application

- the hydraulic traverse beams are bolted to the heating elements to form modules

- each pair of modules consists of one top and one bottom module part, connected by means of 2 traction bolt units

KLIV® - ATEX

- KLIV Flameproof heating element

- I M2 EEx d l according to Design Test Certifi cate BVS 03 ATEX E322

- approved and authorized according to the European Standard 94/9EG dated March 23, 1994 (ATEX)

- in accordance to the material specifi cations of the European Standard EN 60079-0 and EN 60079-1

- each heating element has a stainless steel casing and is equipped with a FLP twin-plug

- this system does not require any additional electric distribution device

- for the safe splicing of all types of conveyor belts underground

- unadjustable end temperature ensured by the ceramic heating system

- certified for 500 – 1100 volts

Any questions? Please contact us here.